Made for mass production, from the inside out

Designed to meet the needs of mass production print shops, the intelligent design of the GTX600 increases efficiency and helps with uptime, and requires less maintenance time* or operator adjustment, resulting in more output. See all the pieces that come together to make the GTX600 our most advanced DTG printer yet by reading through the sections below, or watch the video for additional spec information and explanations.

GTX600 Series Specs

Industrial Construction

Made for mass production, the GTX600 series is industrial in design. Built for durability from the ground up, each machine is capable of running multiple shifts per day, 7 days a week, while producing high quality prints.

- Size - 73.23" x 81.10" x 57.48"

- Weight

- GTX600NB - 1,499 lbs (without ink or cleaning solution)

- GTX600SB Extra Colors - 1,521 lbs (without ink or cleaning solution)

- GTX600NBA Enhanced - 1,521 lbs (without ink or cleaning solution)

- Electrical - 208-220V, 5 Amps; 50/60 Hz

- Solid steel frame with industrial casters for easy movability.

Brother DTG Print Heads

With over 20 years of experience as pioneers in the direct to garment printing decoration industry, we know how valuable a tireless print head is to production. Utilizing the 5th Generation print heads in the GTX600 series, you can expect longer print runs with less waste*, saving you time and money.

- Brother manufactured, 5th generation print heads

- Internal cooling fan for longer print runs

GTX600 Standard GTX600 Extra Colors GTX600 Standard Enhanced 4 Print Heads 6 Print heads 6 Print heads 16 Ink Channels 20 Ink Channels 16 Ink Channels Not Applicable Not Applicable 4 Finishing Fluid Channels High Print Quality

Offer unparalleled print quality on a variety of style of artwork and garments. From photo quality realism, to designs that call for a distressed or weathered finish, the GTX600 series offers four print resolutions to fit each piece's specifications. Being able to control resolution provides the ideal balance of print quality and print speed for each product’s needs, yielding accurate, efficient print operations.

Intelligent Platen Mechanism

Save time and costly mistakes with the GTX600 series intelligent platen system. In concert with Brother's optional SDK, the scan of a barcode on items automatically tells the printer the necessary platen height needed for that garment, and the printer adjusts accordingly. The result is finished products that are precise, consistent, and designs that are correctly adjusted for the specifications of each item in an order, making mass production much easier.

- AC servo motor with screw drive and solid linear rails

- Electronic platen height adjustment and automation availability

Variety of Platen Sizes

Expand your offerings with the GTX600 series wide variety of available platen sizes. From newborn onesies to XXL size garments, artwork can be perfectly resized and proportionate to the garment being printed on.

A large potential print area of 24”x24” means you can take mass production to a greater variety of garments, and our easy to use, quick-change platen systems allow for minimal downtime when switching from one platen to another.

Youth

10x12

Adult

14x16

Oversized

16x18

XL V2

18x22

Jumbo

24x24

Advanced Ink System

Mass production means greater demands in quality and quantity of inks at the ready. With large ink tanks - 7.2 liters of white and 4.3 liters of CMYK - the GTX600 stays at the ready to execute whatever the design demands. Our system is equipped with filtration and degassing features built right in, making sure that when inks reach the print heads they are in their ideal state. The white ink circulation in four key areas ensures that the Titanium Dioxide in the white ink tank stays in suspension, yielding brilliant print quality building off a strong base layer.

Innobella Textile Ink Chemistry

Take your prints and designs beyond what you ever thought possible in direct to garment printing. With Innobella Textile Inks, finished pieces are vibrant and bold — all with color finesse and design accuracy. When printing and curing pieces with the GTX600 series and Innobella Textile Inks, you can be sure it not only looks great upon arrival to your customers, but also that the design will be durable and washable without losing its look. Innobella Textile Inks have scored a 4.0 or higher on ATCC wash tests. And you can feel good about the environmental aspect of your inks as well — GTX600 series inks and pretreatment products are water-based, ECO PASSPORT by OKEO-TEX® certified, CPSIA compliant, and hold GOTS 6.0 certification.

Industrial Maintenance Station

Designed to keep up with the multiple shifts associated with mass production, the GTX600 series is built with industrial grade parts that need less frequent replacement or maintenance, resulting in less downtime*. The GTX600 series also has automated self maintenance features that help ensure every print stays pristine, no matter where it is in the queue.

- Automatic wet capping station keeps the bottom of the print heads ready to print.

- Always wet wiper blades help keep the bottom of the print head clean and free of debris.

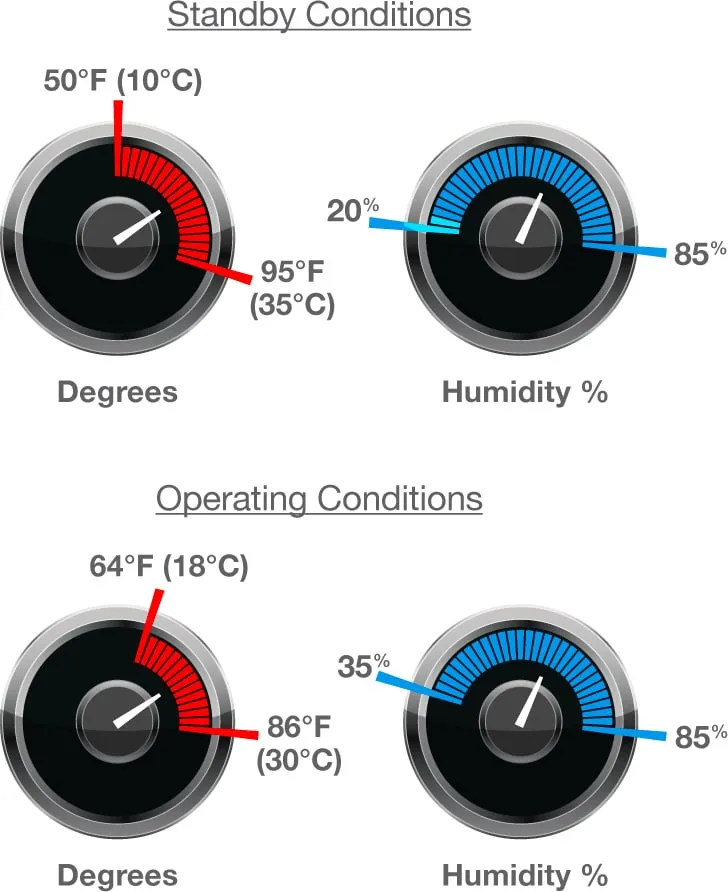

Environment Controls

Managing the environment on the production floor can be a challenge, especially with seasonal changes and large spaces. The GTX600 series helps mitigate this challenge by controlling key environmental conditions within itself, allowing higher production throughput and reduced waste. Internal thermostats and hygrometers keep an eye on the internal conditions of the printer, and will notify the operator of any changes that would result in sub-optimal production.

- Integrated humidifier helps to maintain the ideal printing environment and reduce running costs.

- Built-in mist filters dramatically reduces airborne particles within the printer to protect key components and improve air quality.

Software & Hardware Specs

Whether your shop is Mac or PC based, the GTX600 series printer comes with a print driver that allows your Art Department to create designs in their preferred applications, for maximum compatibility for your production needs. Additionally, the included GTX Graphics Lab printing software performs a variety of design functions including creating a layout; adding text; rotating, sizing and positioning elements; and apply artistic effects, all within one program.

- PC- Windows 11 (64-bit)

- Mac- macOS® Sonoma

Workflow Automation

Maximize your production and operator productivity with built in automation tools that make the GTX600 series easier than ever to use. Utilizing the Brother Software Development Kit (SDK), you can increase automation throughout the process, including but not limited to creating print-ready artwork files, sending files via LAN/USB connections, identifying proper print settings per garment, and monitoring printer performance.

With the help of Brother's 3rd party partners, you can have a total solution in shop, managing your GTX600 series or the entire life cycle of your pieces - from artwork creation, to pretreatment, to curing, and/or shipping in one integrated system.

For more information, visit productiondtg.com/automate.

CADLINK — Complete color management and workflow solution

Specifically designed drivers, color profiles and tool sets to leverage the advanced printing functionality of your GTX600 series. More than RIP software, CADLink's handling of white ink is unique to any RIP provided today.

Brown Digital Linx — Control system integration

Control the whole production process with one resource. Integrate with your online shopping cart, set your pretreat and curing parameters, create an ARX6 file, and manage it all with a single barcode. Then connect with your shipping software.

Mass Production Pretreating & Curing

For vibrant colors and clean prints, pretreatment is essential. The white underbase needs pretreatment to ensure even application of the design. The pretreat fluid should be applied using an industrial spray system and should be cured at 320° F (160° C) for approximately one minute.* Then, a 5 to 7 second heat press will help flatten the fibers in order to prepare the piece for the highest print quality. In a mass production facility, a conveyor oven is recommended, to be used at 320° F (160° C) for three and a half minutes*.

*Time and temperature may vary depending on which manufacturer's dryer is used

At Your Side Commitment

Utilize your GTX600 series with confidence with Brother At Your Side. From the very start, the installation process is a guided tour, utilizing our industry leading LMS system, Brother Academy. This online resource can also be utilized when training new employees as your workforce expands. You can also enhance the benefits of your GTX600 series by having an internal staff member trained to perform maintenance and parts replacement when necessary, further reducing down time.

Warranty Information

At Brother, we stand behind our products, which is why we offer a one-year, 100,000 prints limited warranty on the printer and two years or up to 50,000 prints warranty on the print heads. Expert advice and assistance are also easily available when you need it. Learn more about our limited warranty and support by contacting your Brother Sales Representative, or visiting productionDTG.com/warranty.